The End of an Unsuccessful

Project

I cannot find any air leaks

now and yet the engine is not self sustaining. The force delivered by the

piston seems to be too small to turn the flywheel. I think I have come as far

as I can with this design and it’s time to call the Terrapin project dead.

This is video of me hand-cranking the engine.

Parts of this project

worked quite well:

- A cheap and airtight piston can be made with a

bike inner-tube and a bucket.

- The phase angle between the power piston and

regenerator can be easily adjusted on the fly by using two concentric

axles pinned together by a pointer on the flywheel face.

- A very good regenerator can be made by

alternating aluminum screens with nylon netting. The temperature of the

lower cold chamber did not appreciably increase over the nominal 22C even

thought the top chamber was over 100C, while the engine was being cranked.

- An adjustable and calibrated electrical heat

source can be made from a thrift store toaster and a wall dimmer.

- The power piston stroke length was adjustable

on the fly by moving a control rod.

Parts of the project I had

trouble with:

- The strength and insulation properties of wood

are superb but it is very difficult to make an airtight wooden box.

- The regenerator rod O-ring seals, that I made,

needed to be adjusted very tightly to become airtight. This caused

friction during the regenerator rod travel.

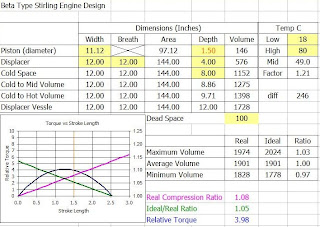

- The engine produced very little power with the

80C temperature gradient. The size of the regenerator vessel must need to

be very large to produce usable power at such temperatures.

- The project was over-budget. The parts that make up the engine cost about $175.

Closing Remarks

Stirling Engines still intrigue me and I may very well

attempt to build another. Here, I learned of several new techniques that I can

apply to future projects. For low temperature-gradient engines, the

displacement vessel must be quite large to develop appreciable power. Building

large airtight insulated vessels that can withstand alternating positive and

negative pressures is challenging.

.jpg)